High Speed Connections & Chucking Mechanisms

Tell A Friend

High Speed Connections

What Are the Different Types of High Speed Handpiece Connections?

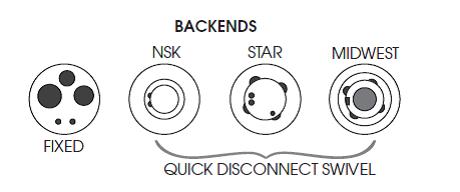

- Handpieces can come with either a fixed back end or a quick disconnect swivel style.

- Both types of back ends can come with 5 different tubing connection configurations (i.e. 2 hole, 4 hole).

Fixed Back

- Does not have a swivel coupler; must be screwed on/off tubing for cleaning and does not swivel.

- Connections are internationally standardized and universal (ISO) so that any brand of handpiece will fit the same tubing connection configuration.

Quick Disconnect

- The handpiece has a hollow back end that can be snapped onto a coupler.

- The coupler is screwed onto the tubing, allowing the handpiece to be quickly attached and removed for cleaning.

What are the Benefits of Quick Disconnect Couplers?

- Easy and fast removal of the handpiece from the tubing.

- Increased dentist comfort, because the swivel reduces the drag of the tubing.

What are the Disadvantages of Quick Disconnect Couplers?

Every major brand of handpiece has its own proprietary connection between the handpiece and the swivel, so handpieces and swivels from different brands are not compatible.

Many manufacturers are beginning to offer handpieces that will fit other brands of couplers, but it appers to us that the KaVo MULTIflex style coupling is winning the battle to become the universal quick connect style.

Chucking Mechanisms

What is a Chucking Mechanism?

The mechanism that allows the handpiece to hold a bur.

What are the Different Types of Chucking Mechanisms?

1. Standard Screw-Type (bur tool-type)

- The spindle and chuck (the parts of the turbine that hold the bur) are separate.

- A bur tool is required to insert and remove the bur; it screws the chuck down into the spindle causing the chuck to tighten around the bur.

- Screw-type chucks can be replaced in repair.

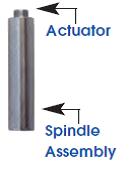

2. Push Button-Type

- The spindle and chuck are a single assembly.

- The push button cap on the handpiece presses on the actuator on the top of the spindle which engages an internal spring component to open or close the chucking mechanism.

- Bur shank size is important – burs with shanks under .0626 or over .0630 cannot be used.

Benefits of Push Button Chucks

- Easy insertion and removal of burs.

Disadvantages of Push Button Chucks

- Do not provide as strong a grip on the bur as screw-type chucks.

- Heavy use can cause the chuck to strip, which will result in poor bur retention.

- Higher cost to purchase.

- Once the chuck fails the whole turbine must be replaced instead of just the chuck.