Diamond Burs

Tell A Friend

Diamond burs are generally used for reducing tooth structures to place crowns or porcelain veneer. Diamonds may also be used to smooth, refine, and polish composite or porcelain

material.

Diamond is the hardest of all known materials. When bonded to stainless steel through a special metallurgical process, it can be used to create a cutting edge with superior cutting

ability and durability. However, compared with carbide burs, diamond burs usually have a more pronounced decrease in cutting effectiveness over time leading to a shorter lifespan.

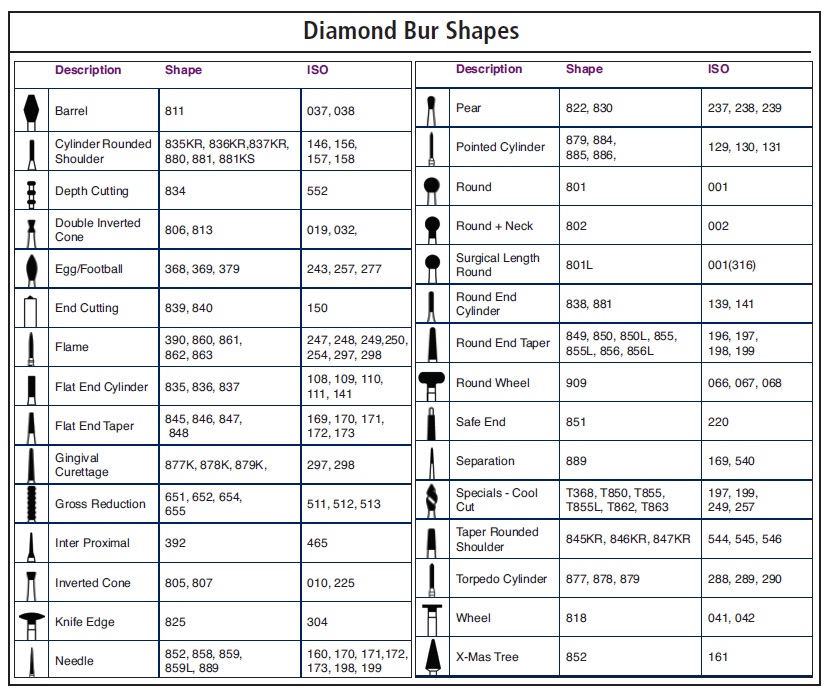

Types of Diamond Bur Shapes

Unlike carbide burs, which are available in a variety of shank types, diamond burs are most commonly friction grip type because they are used primarily in high speed handpieces. However, similar to carbide burs, they come in a variety of head shapes and sizes.

Diamond Bur Grits

Diamond burs also come in a variety of grit sizes. Coarse and super-coarse diamond grits for tooth reduction are the most popular, with fine and super-fine for polishing and smoothing a distant second. Grinding and polishing diamonds should be used to trim and finish micro-filled composites. Coarse grinding tools leave behind striations; fine and extra fine diamonds are suitable for finishing.

Single-Use vs. Multi-Use

Diamond burs come in two types: single-use and multi-use. Single-use diamond burs provide

the convenience of an individually packaged pre-sterilized diamond and a new sharp

instrument with each use. Multiuse diamonds are designed to be re-used for a number of procedures

and hence are more economical. There are many more shapes and grits available in multi-use diamonds.